BrineRefine Chemical Reactor

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Saltworks Technologies is excited to announce the successful delivery of a 3x scaled-up BrineRefine plant to a major semiconductor facility in the USA. This new product offers significantly increased capacity of 3000-4500 m3/day, while maintaining the original 1000-1500 m3/day system’s fully modular design.

By adopting factory-built modular process units over site stick-built options, Saltworks’ clients achieve lower installed cost, lower project risk, faster install and start-up, and a factory-commissioned system with more advanced controls.

The expanded capacity BrineRefine, already deployed across North America’s leading semiconductor and battery manufacturing plants, can now process three times more. In the context of lithium production units, the larger-scale BrineRefine matches with a 15,000 tons per year lithium carbonate plant.

This flexible chemical continuous stir tank reactor (CSTR) has applications across battery manufacturing and recycling, mining operations, and lithium refining. It can recover ions of value, remove ions of concern, and protect downstream assets from scaling compounds.

“Our clients demand larger scale modules, and more work executed on the factory floor vs. at site. We are thrilled to rise to this challenge. We know that site work is four times more costly than factory work. We know that production in a clean well-lit facility, by the same craftspeople each day, translates into higher quality outputs and reduced costs. We also know that commissioning in our facility versus at a remote site enables more thorough code testing and opportunities to build in advanced diagnosis and control features.” said Ross Coleman, VP Engineer of Saltworks.

Saltworks’ BrineRefine continues to lead the way in precision chemical processing enabling higher water and chemical recovery at a lower cost, further positioning the company at the forefront of advanced and cost-effective wastewater treatment solutions across key industries.

Contact our engineers for more information on how BrineRefine can support your project.

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

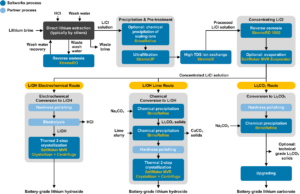

Saltworks brings water mining expertise and advanced desalination technologies to our lithium clients, offering solutions for concentrating, refining, and converting low-grade lithium sources to battery-grade product. We offer higher purity and lower energy processing technology, that boosts yield, removes unit operations, and reduces cost.

The manufacturing of microelectronics generates unique wastewaters. Saltworks can help you to manage wastewater flows from microelectronics production, targeting fluoride, ammonia, metals, and ions, reducing brine waste, and allowing water reuse.

This lithium process flow brochure shows how membrane, thermal, and chemical water technologies fit into various stages of lithium production. Learn how to process lithium to battery-grade, downstream of direct lithium extraction.