Saltworks’ FGD Wastewater Solution Wins POWER Magazine’s Water Award 2020

Saltworks is honoured to receive POWER Magazine’s 2020 Water Award for our ground-breaking ‘chloride kidney’ industrial desalination solution.

Saltworks successfully concluded a 60-day on site pilot at a major US coal fired power plant with 100% up-time. The project treated challenging flue gas desulfurization (FGD) wastewater to selectively remove chlorides for recycle and re-use internal to the coal stack scrubber system. By targeting the key concern—chlorides—this novel selective removal method provides an alternative to expensive complex treatments for discharge as explained in this brief video.

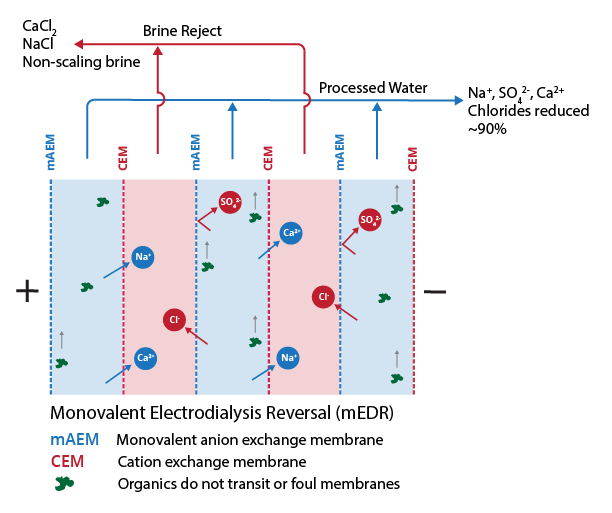

The pilot included a full-scale Saltworks’ FlexEDR Selective Stack, which acts as a “chloride kidney.” Within the stack, Saltworks’ novel monovalent selective anion exchange membranes pull chlorides out of the FGD wastewater under a DC electric field. Outside of stack, a robotized plant enables the process while adjusting to variable water quality and providing valuable data to the operator. The results will be presented at future conferences or contact Saltworks to learn more.

This work was made possible through collaboration with the U.S. Department of Energy (Award Number DE-FE0031678), the Electric Power Research Institute (EPRI) and Southern Company. FlexEDR technology was also developed with support from the National Research Council Canada’s Industrial Research Assistance Program (IRAP), BC Innovative Clean Energy Fund, Western Innovation (WINN) Initiative, and Sustainable Development Technology Canada (SDTC).

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Saltworks is honoured to receive POWER Magazine’s 2020 Water Award for our ground-breaking ‘chloride kidney’ industrial desalination solution.

As regulations on FGD wastewater tighten, additional treatment is required. Often, this is chemically intense, and high cost. The best means to lower treatment costs is to reduce the volume of wastewater generated, usually by increasing internal recycle.

Flue gas desulfurization (FGD) systems are used to remove sulfur dioxide air emissions in coal-fired power plants. FGD wastewater is often saturated with calcium sulfate, while containing both metals and chlorides. Saltworks can help to boost FGD water cycles through selective chloride removal, or treat the FGD wastewater to zero liquid discharge.

FlexEDR is a next-gen electrodialysis reversal (EDR) system for industrial wastewater desalination, solving scaling issues & boosting recovery.