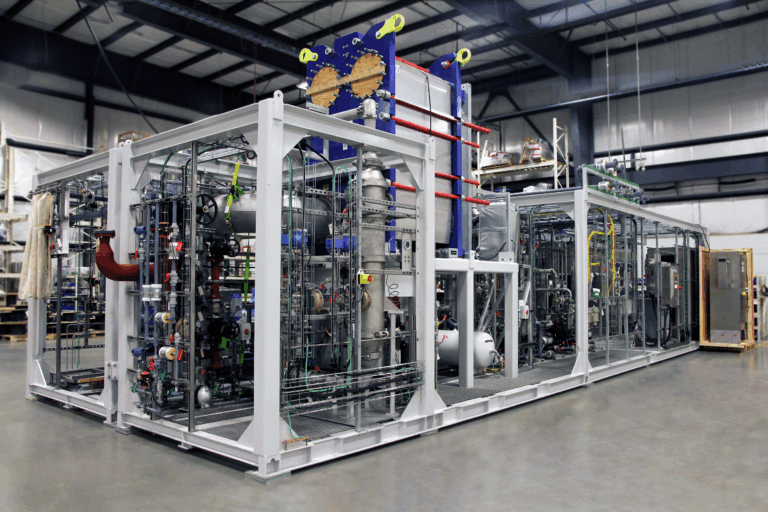

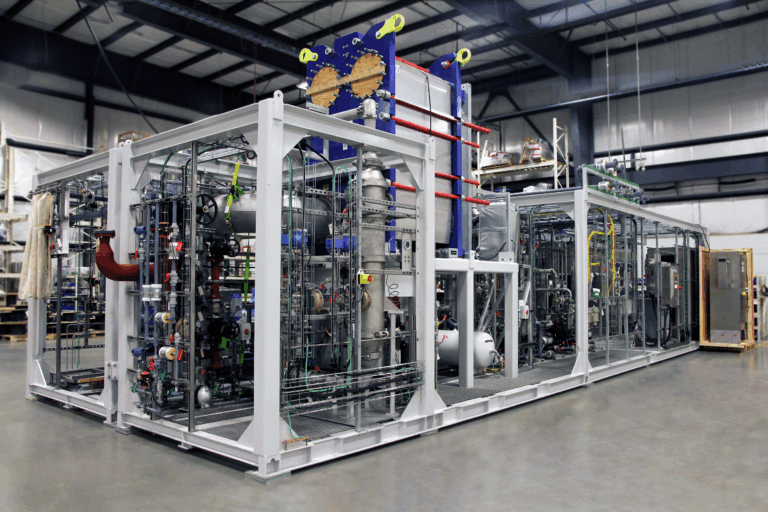

SaltMaker MVR & MSF Evaporative Crystallizers

Modular, next-generation evaporator-crystallizers with intelligent self-diagnosis, self-cleaning, and advanced automation for minimal and true liquid discharge.

Saltworks » Applications » Automotive Manufacturing Water Treatment

Water is essential to many key processes in automotive manufacturing. As the industry continues to grow in scale and complexity, so do its wastewaters. Saltworks can help with these challenges, including:

Heavy metals such as arsenic, nickel, and cobalt can be removed with our BrineRefine and XtremeUF systems. Together, they can concentrate slurries to the extreme, reducing the hydraulic load on filter presses and operators, thereby reducing costs. 99% water recovery can be achieved, with the only waste being a minimized solid filter cake.

Resin sand casting is used in the automotive industry, which generates an air emission. Some projects use wet scrubber systems for air treatment to, producing a sodium sulfate-rich blowdown wastewater requiring treatment. Depending on the specific needs, we can treat this water with one, or combinations of our products:

Saltworks’ brine management solutions can produce clean water from reverse osmosis brines, ion exchange regeneration wastes, and other concentrated saline waters. Our experts can help you to understand your brine minimization options, and the costs involved in taking each incremental step.

For membrane systems, we can maximize recovery from brines and wastewaters with our real-time ion-specific sensors, or our XtremeRO brine concentrator.

After membrane system recovery has been optimized, our thermal desalination solutions from the SaltMaker family of modular, fully packaged industrial evaporator-crystallizers can help you to achieve minimal (MLD) or zero liquid discharge (ZLD). Waste heat-driven options are available.

Contact us to learn more about our solutions for automotive manufacturing wastewaters.

Modular, next-generation evaporator-crystallizers with intelligent self-diagnosis, self-cleaning, and advanced automation for minimal and true liquid discharge.

XtremeUF ceramic and polymeric ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Our XtremeRO and FusionRO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

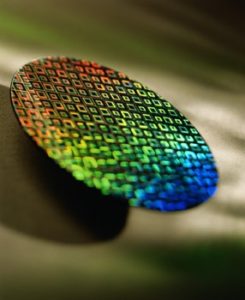

Saltworks brings water mining expertise and advanced desalination technologies to our lithium clients, offering solutions for concentrating, refining, and converting low-grade lithium sources to battery-grade product. We offer higher purity and lower energy processing technology, that boosts yield, removes unit operations, and reduces cost.

With the growing importance of brine management, modernized chemical softening systems can enable economic ultra-high recovery reverse osmosis, minimizing RO brine volume, disposal costs, and reliability risks.

New modular, intelligent, and automated chemical precipitation with a ceramic membrane filtration system eliminates the challenges of chemical overdosing and large footprint requirements.

Saltworks is thrilled to announce the first full-scale order for an industrial Ultra-High Pressure Reverse Osmosis (UHP RO) system with Nitto high performing HYDRANAUTICSTM PRO-XP1 spiral wound membranes rated to 1,800 psi (124 bar).