XtremeUF Ceramic Ultrafiltration

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Saltworks » Applications » Brewery & Distillery Wastewater

Whether industrial or craft-scale, breweries and distilleries use water more efficiently and treat it to higher standards than ever before, all while continuing to create quality beers and spirits for consumers. However, challenges remain, driven by new sustainability goals, more strict regulations, and increasing costs of water procurement.

Wastewaters are generated from processing or from washing. Challenges that prevent discharge or reuse in these industries’ wastewaters include pH, total dissolved solids (TDS) total suspended solids (TSS), biological oxygen demand (BOD), chemical oxygen demand (COD), grease/fats and other organics (e.g. sugars, alcohol, proteins, yeast).

Many brewers and distillers use reverse osmosis (RO) to treat for discharge or reuse. RO rejects TDS and most organics. EDR is an option if only TDS removal is required. EDR and RO both produce freshwater and lower the volume of waste residuals. If water rates or disposal costs are a concern, you may benefit from enhancing system recovery: making more freshwater and less waste volume.

We offer high recovery and ion selective EDR systems that prevent scaling ions from entering brine residuals, enabling much higher recoveries. We also take RO system recoveries to the next level while maintaining performance, cost-effectiveness, and longevity.

Enhance your RO recovery with our core RO product lines:

We know that no two wastewaters are alike and that there is no silver bullet for water. We can augment your existing process with ‘bolt-on’ solutions or design and build a new plant fitted to your needs.

Every case is different and we like getting into the details. Talk to one of our technical leaders today to learn more about solutions for brewery and distillery wastewaters. We can help you by assessing your options and determining the most cost-effective disposal method.

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

This article introduces a new type of ceramic membrane system and explains how it opens the application range. An example of treatment of oil and grease in produced water is provided.

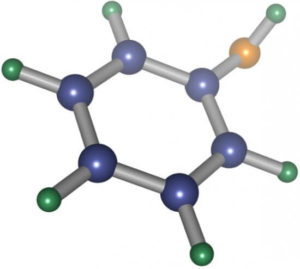

Excessive phenolic compounds are harmful to human health and the environment. Chlorophenols, by-products of chlorinating phenol-containing water, are carcinogens. A treatment system needs to be chosen and engineered carefully, with consideration of specific wastewater chemistry, operating conditions, and economics.

Water is essential to food and beverage manufacturers. Whether you want to reach circular economy goals, or simply improve your bottom line, Saltworks can help. We have solutions for meeting discharge limits, recycling wastewater, and minimizing brine waste.

There is no one-size-fits-all solution to removing ammonia from wastewater. Saltworks can help you understand your options, including hybridizing solutions with biological treatments to boost capacity and reliability, or provide entirely non-biological pathways.