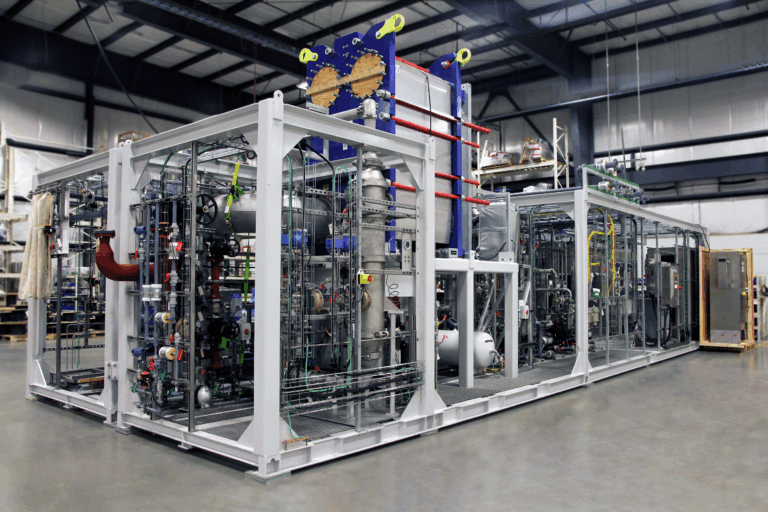

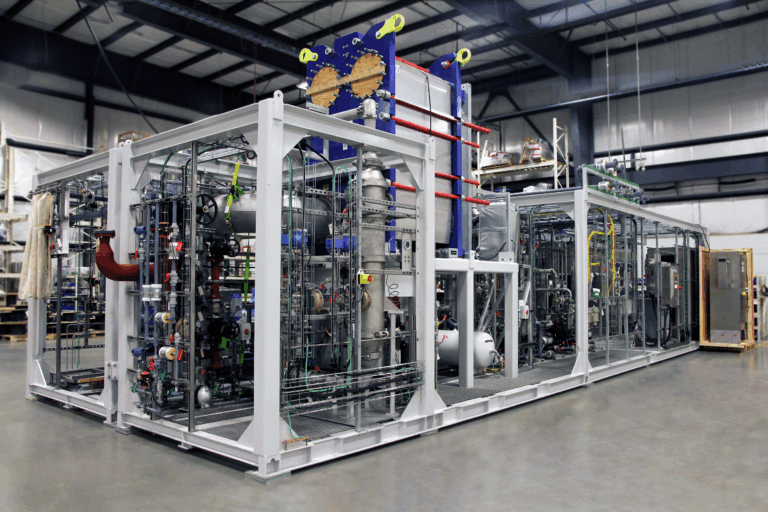

SaltMaker ChilledCrys Crystallizer

ChilledCrys is a novel and highly competitive alternative to expensive evaporators for zero liquid discharge of specific chemistries.

Saltworks » Applications » Battery Manufacturing & Recycling

Recovery of cathode active materials (CAM) and lithium recrystallization

With the shift to electrification of transport and energy storage, demand is increasing for:

Saltworks’ chemical, membrane, and thermal technology systems are optimized for lithium-ion battery manufacturing and recycling operations. We focus on recovery of ions of value, water recycling, and zero liquid discharge treatment of CAM or recycling plant wastewaters.

Cathode active materials (CAM) are the key ingredients in batteries. CAM production facilities produce high-salinity blended wastewaters with precious metals representing a typical $10–60M in annual recovery value.

These wastewaters are often subjected to stringent discharge regulations due to environmental and health risks. Effective treatment can ensure discharge limits are met and significant mineral value is recovered.

On the other end of an electric vehicle or electronic device’s life cycle, spent batteries present the opportunity to economically recover metals of value.

To recover valuable metals such as cobalt, lithium, and nickel, some operators:

The SaltMaker MVR is a forced circulation evaporative crystallizer that concentrates recovered brines and crystallizes solid products. Built-in self-cleaning ensures reliability at optimal capacity while producing a high-purity solid product.

We can engineer an MVR into your total process flow, with full consideration of upstream membrane and chemical systems. When treating CAM wastewaters, Saltworks’ MVR systems can achieve ZLD and recover lithium in resalable form.

The SaltMaker ChilledCrys system selectively precipitates metal sulfates that have a steep temperature-solubility curve, such as nickel sulfate. It also recovers sodium sulfate from wastewater.

When recycling metals from lithium-ion batteries, ChilledCrys can continually separate and remove water and nickel sulfate solids, achieving zero liquid discharge (ZLD) without expensive chemical consumption or evaporation processes.

Saltworks is focused on helping CAM and pCAM producers, lithium-ion battery manufacturers, and recycling operators recover more valuable materials, improve purity and yields, and improve process economics. Contact our industry experts to learn more.

ChilledCrys is a novel and highly competitive alternative to expensive evaporators for zero liquid discharge of specific chemistries.

Modular, next-generation evaporator-crystallizers with intelligent self-diagnosis, self-cleaning, and advanced automation for minimal and true liquid discharge.

XtremeUF ceramic and polymeric ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Saltworks’ Lithium Test Center combines expertise and industry-leading technology to provide innovative solutions for processing lithium resources into battery-grade outputs. The Center is dedicated to de-risking lithium processing projects and accelerating full-scale implementation.

Saltworks has shipped two SaltMaker MVR crystallizers and a SaltMaker ChilledCrys to the electric vehicle (EV) battery industry. These full-scale systems will play an essential role in the production of lithium and nickel—two critical elements in EV batteries.

Saltworks is pleased to announce the production of battery-grade lithium hydroxide from an industrial wastewater. Saltworks’ process harvests lithium hydroxide solids that reach or exceed battery-grade specifications.

Saltworks brings water mining expertise and advanced desalination technologies to our lithium clients, offering solutions for concentrating, refining, and converting low-grade lithium sources to battery-grade product. We offer higher purity and lower energy processing technology, that boosts yield, removes unit operations, and reduces cost.