XtremeUF Ceramic Ultrafiltration

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Saltworks » Applications » PFAS Wastewater Treatment

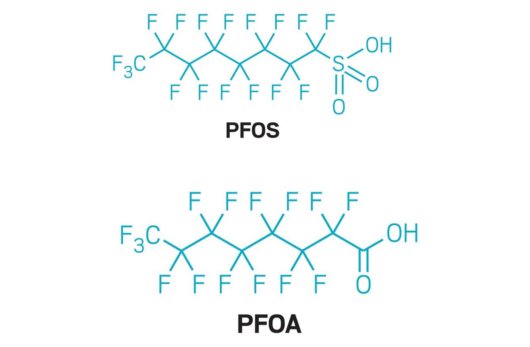

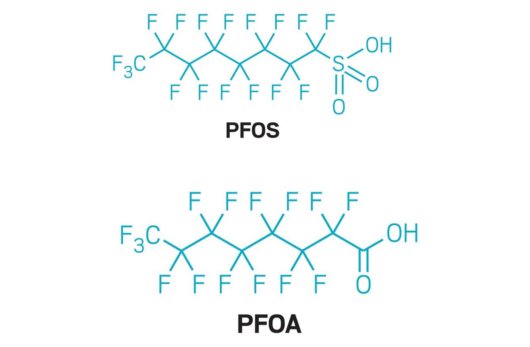

Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS) are a group of man-made carbon-fluorine chemicals, widely used in many industrial and household products. PFAS are “forever chemicals” that do not naturally degrade. They are highly dangerous to human health and the environment.

The accumulation and treatment of PFAS is facing heavy scrutiny in a number of sectors including industrial, municipal, and waste management. PFAS molecules are detected in many wastewaters, owing to their widespread uses in consumer and industrial products. Examples of waters containing PFAS include landfill leachate and aqueous film-forming foam stockpiles.

PFAS treatment systems need to be carefully engineered, with consideration of specific wastewater chemistry, co-contaminant removals, and the pros and the cons of different treatment options.

Alone, or together, there are multiple choices—including new advances—that need to considered to provide an optimal solution:

Saltworks can help you to develop new water treatment systems or upgrade existing ones to treat PFAS. Our treatment professionals will help you assess the cost and performance of relevant options. Contact us. Challenge us.

XtremeUF ceramic ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Open-to-atmosphere evaporator, operating at low temperatures to concentrate brine.

Our XtremeRO and OARO provide industry-leading recovery and reliablity. Concentrate brine, reduce discharge volumes, recover freshwater and more.

PFAS chemicals are often referred to as “forever chemicals” since they do not naturally degrade. Saltworks’ solutions can treat PFAS in water.

Reverse osmosis (RO) is the best available technology to treat landfill leachate for surface discharge. Possible trace volatile organic compounds (VOCs) and ammonia emerging in the RO permeate can be removed with a polishing step to meet the highest discharge standards.

Saltworks has started commissioning what we believe is a first-of-its-kind plant, with much customer interest. The membrane concentrator makes extensive use of reverse osmosis – turbocharged.

Digester wastewaters are by-products of biogas production in anaerobic digesters. They require treatment prior to disposal. To meet regulation compliance, treatment options range from minor interventions such as selective contaminant removal, to major interventions such as minimum and zero liquid discharge (MLD/ZLD).