XtremeUF Ceramic & Polymeric Ultrafiltration

XtremeUF ceramic and polymeric ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Jan 16th 2020

The majority of UF membrane installations are polymeric, which imposes some critical technical limits. Operation at high temperatures, exposure to high/low pH, high TSS concentration, or oils and grease may restrict the longevity and performance of polymeric membranes or make them unsuitable altogether. A typical polymeric membrane module consists of thin hollow fibres (imagine a handful of hollowed-out spaghetti) with flow channels that are 0.2–3 mm in diameter. Failure of polymeric ultrafiltration membranes occurs when these fibres are damaged or blocked, which is especially likely in severe applications.

Ceramic UF membranes are an ultrafiltration solution in the treatment of a wide range of highly impaired wastewaters, such as highly turbid waters, oil & gas produced waters, or slurries. The usage of ceramic membranes has historically been restricted to especially challenging conditions, largely on the grounds of cost. Recent advances in ceramic membrane manufacturing and availability mean that they are now a commodity item, widely available at a lower cost than in the past. For challenging waters, ceramic membranes can now be a much more viable economic choice.

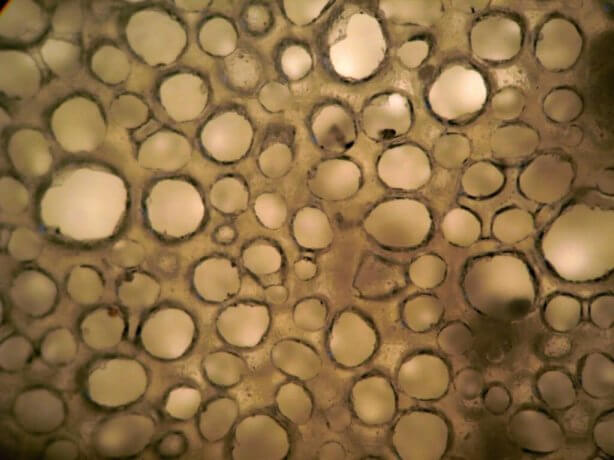

A typical ceramic membrane is composed of a sintered material such as alumina or zirconia (imagine a porous, hard rock that can take a real beating). Unlike polymeric materials, ceramics are stable at high temperatures, will not swell and deform in the presence of oil and grease, and can repeatedly withstand harsh chemical cleans. In addition, commodity ceramic membranes are extruded with flow channel openings of 2–8 mm in diameter, making them less susceptible to blockage in high TSS applications. A ceramic membrane is highly robust and—with the correct automated processes—can recover from performance degradation to maintain operations.

Polymeric (left) and ceramic (right) membranes

To keep ceramic membranes operating at their best, it is important to employ a combination of automated-cleaning methods. The first defense is to achieve high crossflow, minimizing the stagnant zone or boundary layer near the membrane surface. Higher crossflow, or velocity at the membrane surface, will wash particulate away. There are two crossflow velocities: operational and forward flush—whereby velocity is dramatically increased for a short duration by 2-3× to wash away debris. This can require very high flow rates and energy consumption.

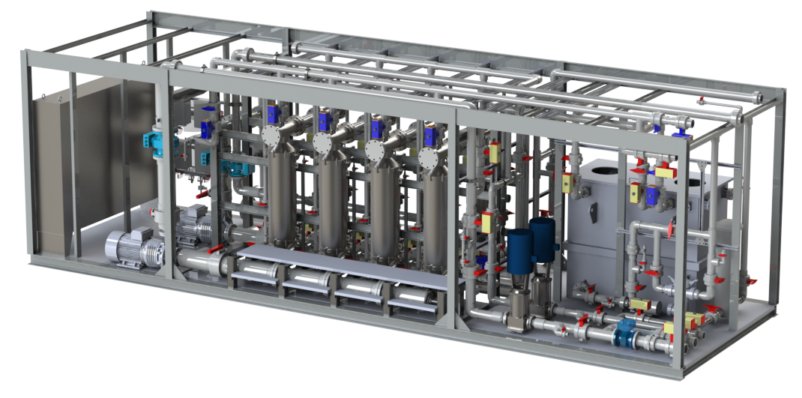

Saltworks has developed a novel hydraulic system that minimizes energy consumption and back pressure while maximizing velocity at the membrane surface. Our forward flushes are done in a smart way, to increase the crossflow to wash away any particulate while minimizing the operational impact on the system.

Backwashing is another cleaning method that incorporates hydraulic pressure to push particulate off the membrane surface. Chemical cleaning is comparatively expensive and used less frequently. Nevertheless, we build in and automate all of these systems.

Saltworks’ automated XtremeUF system performs cleaning in an intelligent and responsive manner, based on continuous online monitoring of membrane performance. The system selects from multiple levels of cleaning cycles to enable the membrane to maintain flux without irreversibly fouling. We clean only when and how it is necessary. This maintains performance and uptime while minimizing energy consumption.

Saltworks focuses on treating the toughest waters. We identified a gap for XtremeUF on the basis of three observations: significant demand for treating waters that are too challenging for polymeric UF; reduction in ceramic membrane prices; and an opportunity to apply our know-how to implement intelligent automation in cleaning. To produce an XtremeUF system, we package commodity ceramic UF membranes into well-engineered and intelligently automated systems that can take slurry concentrations to new levels.

We needed XtremeUF to meet the following criteria:

Enhanced oil recovery (EOR) maximizes reservoir production by injecting water to push out more oil. While reinjecting the water may be desirable, the water becomes saline and picks up particulate during the process. The water may also have been treated with polymers to increase its viscosity, to push out even more oil.

This is a prime example of where traditional polymeric UF membranes do not fit, while ceramic membranes do. XtremeUF can produce clean filtrate—removing oils, grease, polymers and particulate—from produced water. This allows the injection/reinjection of high-quality water into a reservoir undergoing enhanced oil recovery, reducing the potential for reservoir plugging. It can also facilitate the ocean discharge of produced water, by removing all of the above prior to discharge.

Here, you can read about a pilot test where an XtremeUF system was dispatched to a live oil field in an EOR scenario, and its reliable operations were successfully demonstrated.

Can XtremeUF help you to meet your targets? Is ceramic or polymeric filtration right for you? Our Saltworks experts are ready to test your water to establish feasibility and indicate site performance. Contact us to learn more.

You can also see our spec sheet to see where polymeric membranes stop and ceramic UF membranes start.

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

XtremeUF ceramic and polymeric ultrafiltration removes oils, grease, precipitated by-products, particulate, microbes, and suspended solids.

Digester wastewaters are by-products of biogas production in anaerobic digesters. They require treatment prior to disposal. To meet regulation compliance, treatment options range from minor interventions such as selective contaminant removal, to major interventions such as minimum and zero liquid discharge (MLD/ZLD).

With the growing importance of brine management, modernized chemical softening systems can enable economic ultra-high recovery reverse osmosis, minimizing RO brine volume, disposal costs, and reliability risks.

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).