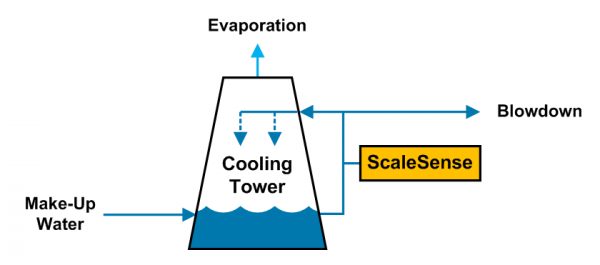

Achieving 70x Cooling Tower Blowdown Volume Reduction

Cooling towers are used by industrial plants to reject waste heat to atmosphere. A portion of the cooling water is blown down after a number of cycles of concentration, before the ions and metals reach their scaling limits. This blowdown requires management.