Saltworks’ FGD Wastewater Solution Wins POWER Magazine’s Water Award 2020

Saltworks is honoured to receive POWER Magazine’s 2020 Water Award for our ground-breaking ‘chloride kidney’ industrial desalination solution.

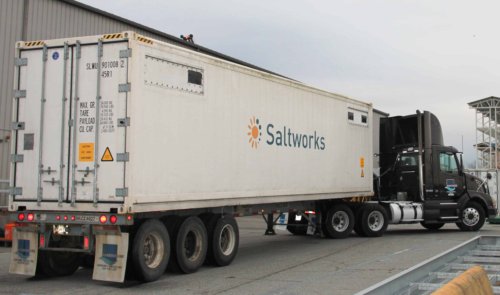

Saltworks has shipped a novel FlexEDR system to the southern United States that will clean up coal-fired power wastewater. Flue gas desulfurization (FGD) wastewater is a byproduct of sulfur scrubbers, installed to prevent acid rain from coal plants. Cost-effective FGD water treatment has been an elusive goal, but a solution is on the horizon.

Saltworks’ novel system will use proprietary IonFlux ion exchange membranes to selectively remove chlorides, enabling internal recycling of water. This simple single step recycle process prevents the need for very complex and expensive full treatment. The innovation is partially enabled by a new ion-specific sensor, developed by Saltworks, that can also help miners and the oil and gas industry measure and adjust to sulfate or calcium load in real time. This material is based upon work supported by the Department of Energy under Award Number DE-FE0031678.

Derek Mandel, Technology Director for FlexEDR commented: “Nicknamed the ‘chloride kidney’ and tested for over two years, we look forward to proving the solution at site with commercial systems following shortly. The product is built on the backbone of 50-year-old Electrodialysis Reversal (EDR) technology, which is the second most widely used membrane desalination tech, with full scale production already in place.”

After completing its U.S. tour, the plant will be sent to China. Over 60% of Chinese power still comes from coal, with increasing concern and regulatory pressure to treat FGD wastewater and protect China’s aquatic environment. The ‘chloride kidney’ has applications outside of FGD, selectively removing troublesome ions to enable water reuse, for example in agriculture, oil refining, and gold extraction.

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Saltworks is honoured to receive POWER Magazine’s 2020 Water Award for our ground-breaking ‘chloride kidney’ industrial desalination solution.

As regulations on FGD wastewater tighten, additional treatment is required. Often, this is chemically intense, and high cost. The best means to lower treatment costs is to reduce the volume of wastewater generated, usually by increasing internal recycle.

Flue gas desulfurization (FGD) systems are used to remove sulfur dioxide air emissions in coal-fired power plants. FGD wastewater is often saturated with calcium sulfate, while containing both metals and chlorides. Saltworks can help to boost FGD water cycles through selective chloride removal, or treat the FGD wastewater to zero liquid discharge.

FlexEDR is a next-gen electrodialysis reversal (EDR) system for industrial wastewater desalination, solving scaling issues & boosting recovery.