SaltMaker Evaporators & Crystallizers

Our SaltMaker modular evaporators and crystallizers turn almost any wastewater into clean water, minimal liquid discharge (MLD) brines or zero liquid discharge (ZLD) solids.

Saltworks is moving into two larger facilities, while maintaining its seafront test site. Saltworks is presently strategically located on Vancouver sea shore, complete with a seawater intake, outfall, and world class R&D and pilot facilities. We are keeping our R&D and pilots at the seafront. We are moving our manufacturing to larger facilities in order to fulfill market demand.

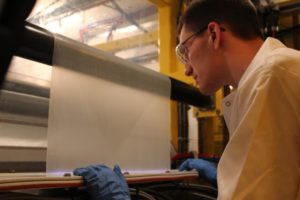

Today, we started moving our IonFlux ion exchange membrane production and ElectroChem stack production to a 14,000 SFT facility pictured below. Over the coming months, we will move in our membrane and stack production line, with space to add up to three more production lines. This will provide production capacity of up to 100,000 m2 per year—enough to serve fifty industrial-scale water treatment plants per year.

In August, we will move our SaltMaker evaporator crystallizer production to a new 65,000 SFT facility. This will enable production and commissioning of up to twenty SaltMakers per year for delivery to the global market. These investments are being made from the proceeds from past customer projects coupled with capital invested by shareholders.

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Our SaltMaker modular evaporators and crystallizers turn almost any wastewater into clean water, minimal liquid discharge (MLD) brines or zero liquid discharge (ZLD) solids.

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).

IonFlux Ion Exchange Membranes deliver best-in-class performance for electrodialysis and ion separation applications using new generation polymer chemistry.

FlexEDR is a next-gen electrodialysis reversal (EDR) system for industrial wastewater desalination, solving scaling issues & boosting recovery.