Saltworks’ FGD Wastewater Solution Wins POWER Magazine’s Water Award 2020

Saltworks is honoured to receive POWER Magazine’s 2020 Water Award for our ground-breaking ‘chloride kidney’ industrial desalination solution.

Saltworks will accelerate commercialization of its FlexEDR Ammonia technology with recently awarded funding from Sustainable Development Technology Canada (SDTC) aimed at both municipal and industrial wastewater treatment applications.

FlexEDR Ammonia reliably removes ammonia from municipal wastewater, landfill leachate, and other waste streams. Ammonia in wastewater is a growing problem due to its detrimental impact on aquatic ecosystems.

FlexEDR Ammonia works in extreme conditions where conventional approaches are unable to operate. It is insensitive to temperature, salinity, or varying ammonia loads and is not affected by contaminants that challenge traditional biological systems. FlexEDR Ammonia also turbocharges biologically based wastewater treatment plants by removing ammonia from centrate, their concentrated ammonia stream, effectively increasing plant capacity.

“Sustainable Development Technology Canada is very proud to support the commercialization of Saltworks’ innovative technology,” said Leah Lawrence, SDTC President and Chief Executive Officer. “This project will create green jobs for the local economy, increase efficiency in the sector and provide economic and environmental benefits for all Canadians.”

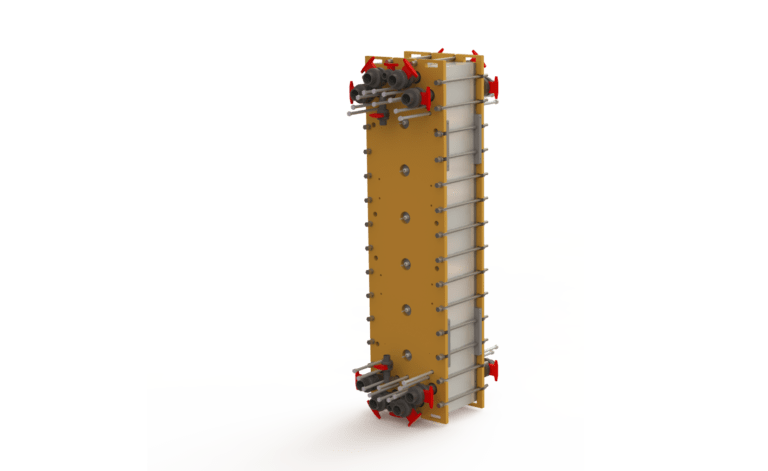

Saltworks has operated FlexEDR Ammonia on municipal wastewater treatment plant centrate and landfill leachate. The technology uses Saltworks’ ElectroChem platform with a different IonFlux membrane and process. Commercial production is based on widely used electrodialysis reversal (EDR) equipment, including the ion exchange membranes, stacks, and plants built by Saltworks.

Saltworks is presently seeking additional site implementation partners. Read more about ammonia wastewater treatment.

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

Saltworks is honoured to receive POWER Magazine’s 2020 Water Award for our ground-breaking ‘chloride kidney’ industrial desalination solution.

There is no one-size-fits-all solution to removing ammonia from wastewater. Saltworks can help you understand your options, including hybridizing solutions with biological treatments to boost capacity and reliability, or provide entirely non-biological pathways.

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).

FlexEDR is a next-gen electrodialysis reversal (EDR) system for industrial wastewater desalination, solving scaling issues & boosting recovery.