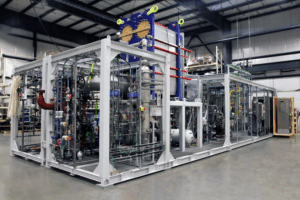

SaltMaker ChilledCrys Crystallizer

ChilledCrys is a novel and highly competitive alternative to expensive evaporators for zero liquid discharge of specific chemistries.

Convention teaches that zero liquid discharge (ZLD) crystallizers require the energy-intensive boiling of water to produce solids. Our engineers recently broke that convention and helped a mining client achieve solid salt production in a novel membrane-chiller hybrid plant. The pilot project used ultra-high pressure reverse osmosis (UHP-RO) technology to replace a thermal evaporator; providing the client with an option for lower capital and operating costs over a conventional thermal ZLD option (which Saltworks also builds).

Our engineers hybridized UHP-RO with a chilled crystallizer system, in a semi-closed loop that concentrates water, extracts solid salt, and repeats the cycle. The UHP-RO system can concentrate certain salts (e.g. sodium sulfate) to over 20% by mass. Examples of suitable ions include: Na+, K+, NH4+, CO32-, and SO42-. The concentrated brine solution then enters our chilled crystallizer, which takes advantage of steep solubility changes with temperature. There, the solution cools, resulting in the formation of salt crystals, which can be separated and removed.

After cooling and salt extraction, the residual brine liquor has a lower dissolved salt content (~10%) and can be warmed up and recycled once again through the UHP-RO system. A heat pump is used to simultaneously cool one part of the circuit while heating the other — presenting considerable energy efficiency savings. As the loop operates, it continuously produces reverse osmosis quality permeate and solid salt crystals, while being replenished with make-up wastewater. No boiling means less energy consumed and lower costs.

The ChilledCrys membrane crystallizer system is not a silver bullet that is suitable for all brines. However, for certain saltwater brines found in industry (e.g. sodium sulfate scrubber wastewaters), ChilledCrys can present considerable cost and energy savings. As with most things in water: it depends on the chemistry. Highly soluble ions will not crystallize through chilling, and organics or silica that accumulate require extraction. We have solutions and our engineers are ready to run detailed assessments for your water challenges.

Contact us with your chemistry for an assessment. Find out if ChilledCrys can provide your project with the step change in ZLD costs that many are seeking.

Saltworks Technologies is a leader in the development and delivery of solutions for industrial wastewater treatment and lithium refining. By working with customers to understand their unique challenges and focusing on continuous innovation, Saltworks’ solutions provide best-in-class performance and reliability. From its headquarters in Richmond, BC, Canada, Saltworks’ team designs, builds, and operates full-scale plants, and offers comprehensive onsite and offsite testing services with its fleet of mobile pilots.

ChilledCrys is a novel and highly competitive alternative to expensive evaporators for zero liquid discharge of specific chemistries.

Our SaltMaker modular evaporators and crystallizers turn almost any wastewater into clean water, minimal liquid discharge (MLD) brines or zero liquid discharge (ZLD) solids.

Modular, next-generation evaporator-crystallizers with intelligent self-diagnosis, self-cleaning, and advanced automation for minimal and true liquid discharge.

Zero liquid discharge (ZLD) is an engineering approach to water treatment where all water is recovered and contaminants are reduced to solid waste.