Industrial Desalination Systems

Saltworks specializes in designing and delivering full-scale, modular systems for industrial water desalination and lithium refining. Our digital modular systems are end-to-end solutions designed for rapid installation, operational ease and high performance.

Our packages include:

- All core process unit operations delivered pre-commissioning and ready to install.

- Flange-to-flange complete system, ready to install, start-up, and future-proof with built-in digitization.

- All interconnecting pipework, pipe bridges, and inter-skid cabling.

- All feed pumps, feed and discharge controls, and chemical delivery systems.

- Single access, total plant control system with advanced intelligence to reduce labor, increase up-time, and optimize performance.

- Comprehensive spare parts, documentation, and operator training program.

Industrial Desalination Systems

Saltworks offers three distinct industrial desalination systems:

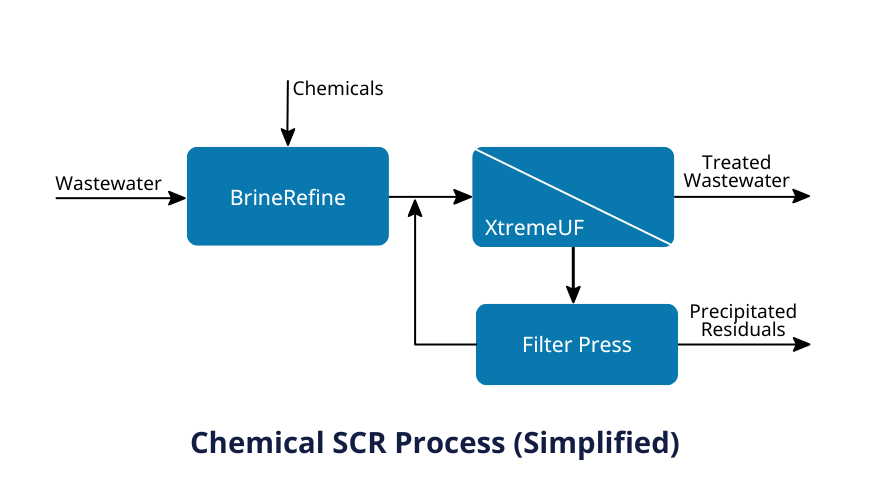

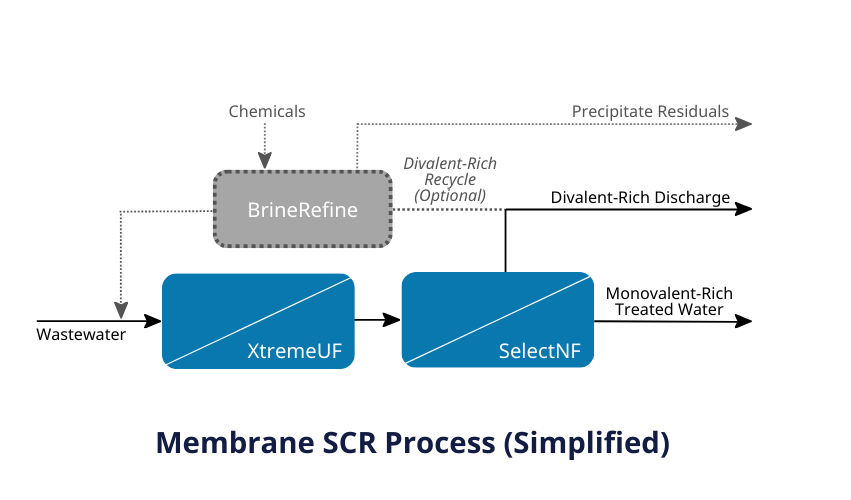

Saltworks’ selective contaminant removal systems cost-effectively recover or treat specific ions. By surgically targeting specific ions with SCR, more expensive full-stream treatment may be avoided while also minimizing waste residuals.

Our physical and chemical SCR systems are flexible and can target a variety of compounds. Use cases include:

- Targeted treatment of hydrofluoric acid waste, heavy metals, sulfates.

- Removal of scaling ions including hardness, metals and silica.

- Resource recovery of valuable metals such as cobalt or nutrients such as phosphorous.

- Selective nanofiltration to produce a permeate for re-use while rejecting divalent ions.

Core technologies: BrineRefine, XtremeUF, SelectNF

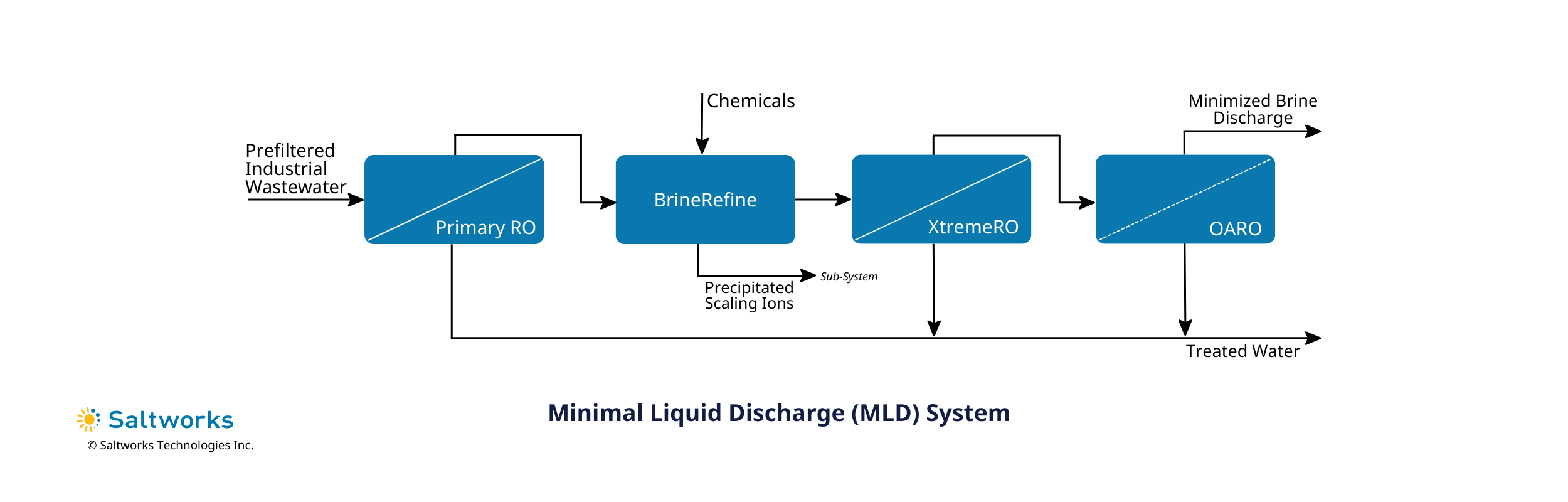

Saltworks’ minimal liquid discharge systems maximize freshwater recovery while minimizing the remaining saline brine. Our MLD systems employ the optimal blend of advanced reverse osmosis (RO) technologies to cost-effectively and reliably treat your specific wastewater.

Common reverse osmosis stages include:

- 600 psi initial RO recovery generating a brine, which may be saturated in scaling ions.

- Selective contaminant removal (SCR) of scaling ions.

- 1200 psi RO (seawater or SWRO) to recover additional water.

- 1800 psi RO (ultra high pressure or UHP RO) to boost recovery

- FusionRO (UPH-RO-NF) to achieve the highest possible membrane-based water recovery and brine concentration.

Core technologies: BrineRefine, XtremeUF, XtremeRO/FusionRO

Saltworks’ zero liquid discharge systems economically treat saline brines to produce solid salt while recovering remaining water as a distillate. ZLD is needed when brine rejects cannot be cost-effectively disposed of or stored.

Our ZLD systems often start with a membrane-based MLD system, followed by our advanced evaporator and crystallizer options. Our ZLD systems are designed to treat highly impacted waters built to handle scaling ions while self-cleaning and minimizing chemical consumption.

Core technologies: BrineRefine, XtremeUF, XtremeRO/FusionRO, SaltMaker MVR

Lithium Refining Systems

Saltworks offers advanced lithium refining systems:

Our modular and advanced lithium refining systems (LRS) cost-effectively refine both hard rock and brine feedstocks to produce lithium carbonate and lithium hydroxide with 99.9% purity.

Saltworks’ lithium refining activities focus on:

- Direct lithium extraction (DLE) post-processing via our complete concentrate, refine and conversion (CRC) systems to process brine to battery grade lithium chemicals. See process.

- Spodumene processing systems that accept post-leach lithium solutions to produce lithium carbonate or lithium hydroxide. See process.

- Discrete unit operations as part of large lithium refining such as:

- Modernized and modular lithium carbonation systems enabling ease of operation.

- Advanced lithium hydroxide crystallizers.

- Discrete impurity removal systems to target hardness and/or boron.

- Ultra-high water recovery systems to generate freshwater and concentrate lithium, including ultra high-pressure reverse osmosis and nanofiltratiton (FusionRO).

Core technologies: BrineRefine, XtremeUF, XtremeRO/FusionRO, SaltMaker MVR, LcRx