ScaleSense: Real-Time TDS Sensor/Analyzer

ScaleSense is an automated, real-time sensor that measures calcium, barium, sulfate, and silica in high TDS brines.

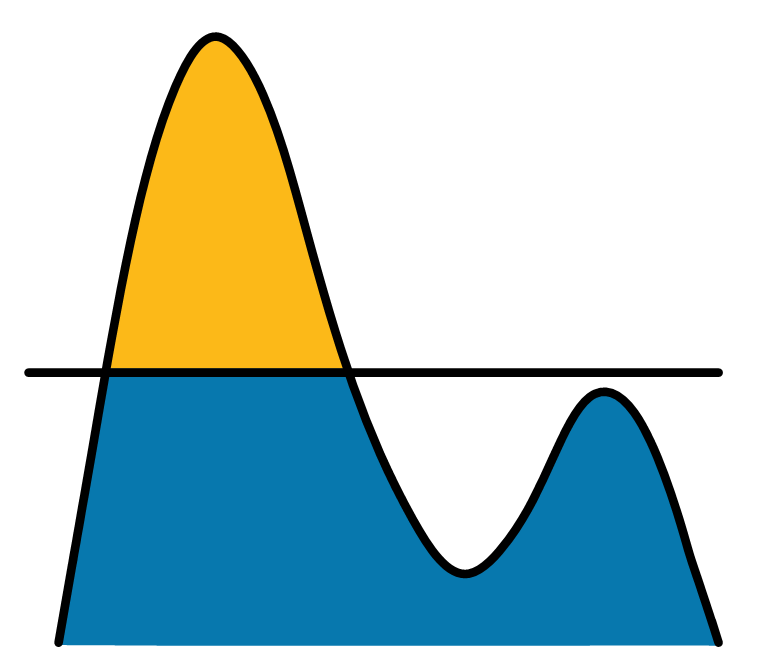

To maintain TDS compliance, you may not need to treat the full flow, to the full extent. This allows ‘peak shaving’ opportunities, i.e. lowering the TDS by the optimal amount so that you remain in compliance, while still taking full advantage of your discharge limit.

Peak shaving requires sound process engineering and control, as well as high recovery systems to minimize TDS waste shaved from your peaks. If your project is reaching or exceeding your TDS discharge limit, Saltworks can help.

Your process may be permitted to discharge 3,000 mg/L TDS, but you may see discharges approaching 4,500 mg/L. To resolve this, you don’t need to fully treat the entire flow. You only need to treat and manage the waste generated from the difference (i.e. 4,500 – 3,000 = 1,500 mg/L). We have options and solutions for you:

We can help you work through a TDS Peak Shaving analysis. Together, we can strategize to lower your treatment costs, while also producing less residuals such as concentrated brine or solid salt.

Contact us with your wastewater analysis, treatment goals, and flow rates. If your TDS discharge fluctuates, be sure to let us know. We may be able to save you money and waste generated through sound process control.

ScaleSense is an automated, real-time sensor that measures calcium, barium, sulfate, and silica in high TDS brines.

Open-to-atmosphere evaporator, operating at low temperatures to concentrate brine.

BrineRefine is a continuous stirred tank reactor (CSTR) that executes diverse chemical reactions efficiently and with precision.

The many options for managing brine, a term for saline wastewater from industrial processes, fall under two categories: brine treatment and brine disposal. Brine treatment involves desalinating the brine for reuse and producing a concentrated brine (lower liquid waste volume), or residual solids (zero liquid discharge).

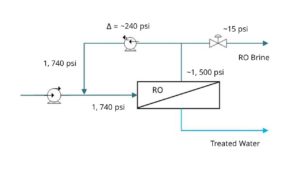

New ultra-high pressure reverse osmosis technology for minimal liquid discharge (MLD) can reduce brine management costs by three times relative to evaporators. Modernized chemical softening technology is available to prevent scaling and enable recovery up to the osmotic pressure limit at 1,200 or 1,740 psi.

Real-time measurement provides prompt feedback for controls. A real-time sensor can help to optimize your process, reduce risk, and minimize operational and maintenance demand. Saltworks has developed a new real-time sensor—that is simple and robust—to operate in the high-TDS range.

Targeting specific ions for removal can be the most cost-efficient way to treat a wastewater flow. Saltworks has treatment and sensing solutions available to treat ions and other species, making water suitable for discharge or re-use.